Key Types of Scaffolding in Construction

Whether you're building skyscrapers or working on large industrial projects, one component consistently stands between success and setback in a construction project: scaffolding. These temporary structures provide workers with a safe and stable platform to perform tasks at height, ranging from painting and maintenance to full-scale structural builds.

Over the decades, scaffolding in construction has evolved dramatically, shifting from basic wooden platforms to high-tech, modular systems designed with safety, flexibility, and efficiency in mind.

The Evolution and Importance of Scaffolding

Historically, scaffolding was made of wood and manually assembled. Modern construction scaffolding is now built with steel or aluminum for added durability and load-bearing capacity. Innovations in design — such as modular scaffold systems — allow for faster assembly, disassembly, and reconfiguration, making them more adaptable to various site conditions.

With increased focus on environmental impact, eco-friendly scaffolding options built with recyclable materials have gained traction. Simultaneously, stricter safety regulations, such as those from OSHA, continue to shape how scaffolding is designed, assembled, and maintained.

Types of Scaffolding in Construction

There are many types of scaffolding available today, each tailored to meet specific construction needs. Selecting the right scaffold system improves project efficiency while maintaining compliance.

Let’s explore ten key types of scaffolding in construction and where each scaffolding type is best applied:

- Frame Scaffolding: One of the most used scaffolding types, frame scaffolding consists of steel frames connected by cross braces, providing strong support for general construction work.

- Suspended Scaffolding: Using ropes or chains from the top of a structure, suspended scaffolding is ideal for high-rise projects; suspended scaffolding can support window washing or facade repairs where ground access is limited.

- Rolling Scaffolding: Equipped with caster wheels, rolling scaffolding allows for mobility and is useful for indoor projects or areas that require frequent repositioning.

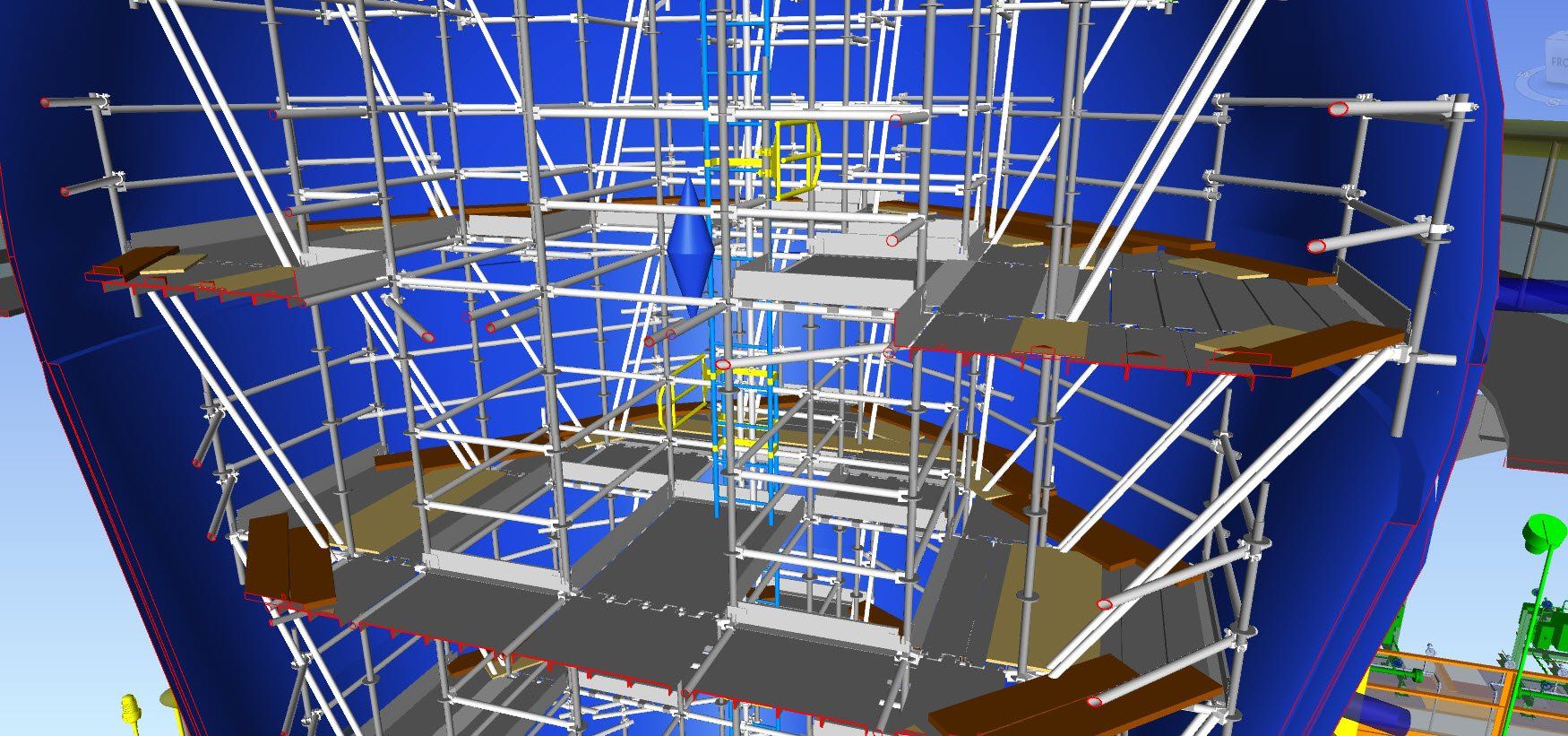

- System Scaffolding: Also known as modular scaffolding, these pre-engineered systems are fast to set up and highly versatile — perfect for complex structures or irregular building designs.

- Cantilever Scaffolding: Supported only on one side, cantilever scaffolding is often used when the ground space directly below the work area must remain clear. Cantilever scaffolding is useful in bridge construction or urban sites.

- Tube and Clamp Scaffolding: Composed of steel tubes and clamps, this system offers exceptional flexibility for creating custom shapes and adapting to unconventional building contours.

- Staircase Scaffolding: To make it safer for workers to move between levels during large-scale projects, staircase scaffolding integrates stair access directly.

- Shoring Scaffolding: Not used as a working platform, shoring scaffolding provides temporary structural support during construction, especially when walls or ceilings are under repair or alteration.

- Bridge Scaffolding: Designed to span across roads or other obstacles, bridge scaffolding provides a safe walkway or workspace above ongoing activity below.

- Trestle Scaffolding: Lightweight and typically short-term, trestle scaffolding is used for low-elevation projects; trestle scaffolding is especially useful for interior painting, installations, or minor repairs.

By understanding both the advantages and applications of each type, construction professionals can make informed scaffold selections that support productivity and safety on-site.

The Importance of Scaffolding Safety

Scaffolding safety is critical for preventing accidents and maintaining compliance with construction regulations. OSHA outlines strict safety standards, such as proper load calculations, guardrails, fall arrest systems, and regular inspections.

Common risks — including improper assembly, overloaded platforms, or falls from heights — can be avoided by adhering to the best practices below:

- Regularly inspect all scaffolding components before use

- Train workers on assembly and dismantling procedures

- Use personal protective equipment (PPE) like helmets, harnesses, and slip-resistant boots

- Follow manufacturer load limits and avoid improvisations

Proper scaffolding protocols protect not only the workers on-site, but also the pedestrians and equipment below. Prioritizing safety at every stage also fosters a culture of responsibility.

Benefits of Using Scaffolding in Construction

Beyond safety, scaffolding can elevate project outcomes across every phase of construction. Its strategic use offers numerous advantages:

- Efficiency: Provides easy access to elevated work areas, enabling quicker task completion

- Safety: Reduces the risk of falls and injuries, especially when combined with proper PPE and training

- Cost-Effectiveness: Minimizes delays and accidents, contributing to timely project delivery

- Adaptability: Can be tailored to different designs, weather conditions, and site constraints

- Versatility: Suitable for a wide range of construction environments — from outdoor buildings to indoor maintenance work

As the industry continues to evolve, new trends are influencing how scaffolding is built and used. Lightweight materials like aluminum are gaining popularity for their ease of transport, while modular scaffolding systems are incorporating digital tools, such as 3D planning software and sensor-based load monitoring, to enhance design precision. And as sustainability becomes a central concern in construction, green engineering practices will continue to emerge.

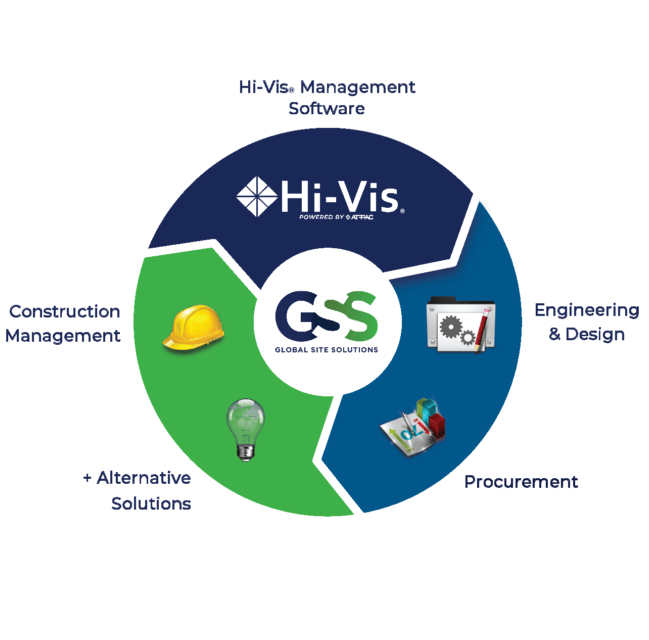

Ready to streamline your next project? Explore how our Hi-Vis® software can enhance safety and efficiency. For more support, let’s talk about your scaffolding needs.

You might also like

GSS Blog